Posted on September 18, 2024 frank botman Aerospace

Industries ranging from manufacturing plants to processing facilities rely heavily on the dependable operation of motors to ensure smooth production. Found within motor control systems is a component called the drive, which regulates speed and torque. Among the different types of motor drives, DC drives stand out due to their ability to provide consistent and reliable control over motor functions. In this blog, we will explore the importance of motor control systems in industrial applications, then take a closer look at what DC drives are and the advantages they offer in various industrial settings.

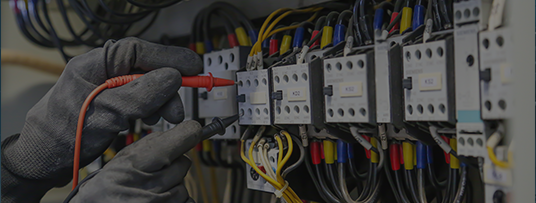

Motor control systems play a vital role in industrial settings by regulating the performance of motors that power equipment like conveyors, pumps, fans, and robotics. Without effective control systems, precise adjustment of motor speed, torque, and direction would be nearly impossible, leading to reduced efficiency. Motor drives, whether they be AC or DC variants, form the backbone of these systems, ensuring that machinery operates within desired parameters.

DC drives in particular have garnered attention for their simplicity and effectiveness. They serve to convert an input of AC or DC power into a variable DC output, which is then used to control the speed and torque of a DC motor by adjusting the voltage and current supplied to it. The primary components are typically a rectifier for conversion and a control system that modulates output to match the desired motor performance. To meet specific needs, there are many designs of DC drives, including chopper and thyristor-based types. Chopper drives, for instance, use high-frequency switching to achieve efficient voltage control, while thyristor-based drives utilize controlled rectifiers to modulate the power supply.

There are many advantages to using DC drives, like their high starting torque that is essential for heavy machinery requiring significant force to start. Moreover, unlike AC drives, which may experience fluctuations at lower speeds, DC drives offer stable control. As such, DC drives are often more efficient in terms of energy consumption, especially in applications where variable speed control is needed. This translates into cost savings for industries looking to optimize their operations while minimizing their environmental footprint. Another key advantage of DC drives is their straightforward control circuitry, utilizing simple designs that are easier to maintain and troubleshoot. This results in reduced downtime and lower maintenance costs, as repairs can be performed quickly and without specialized equipment.

As a result of their dependable operation, DC drives have found a wide range of applications across various industrial sectors. For instance, they are commonly used in manufacturing, where accurate control over motor speed is necessary to maintain consistent product quality in processes like assembly lines, material handling, and packaging. In industries like food and beverage production, DC drives help deliver steady timing to avoid bottlenecks and ensure uniform output. Conveyor systems specifically, which are a staple of both manufacturing and distribution facilities, benefit immensely from the smooth speed regulation provided by DC drives to accommodate different types of products and tasks.

In addition, DC drives are essential in heavy-duty applications like cranes and hoists, where their high starting torque is a critical advantage. In industries such as construction, mining, and shipbuilding, where cranes and hoists are frequently used to move large and bulky materials, DC drives provide the precise control needed for safe handling. Additionally, they are advantageous in situations where fine motor control is necessary to move heavy materials into place without risk of accidents or misalignment. Overall, DC drives offer numerous advantages and serve as a reliable choice for industries that prioritize stable speed control.

On Find Automation Parts, you can procure DC drives and various other products you may need for operations with time and cost savings. With over 2 billion new, used, obsolete, and hard-to-find components ready for purchase, we invite you to peruse our inventory at your own pace with our robust search engine or curated catalogs. As you come across parts of interest, keep in mind that our online RFQ forms are available for you to fill out at any time to rapidly receive competitive quotes from our experts. Moreover, as we are accessible around the clock to assist, you can reach out by phone or email at any time to ask questions or get started on procurement. Get in touch with us at your earliest convenience and see how we can seamlessly fulfill your part requirements!

The only independent

The only independent

All Orders are Fulfilled in the U.S.A.

All Orders are Fulfilled in the U.S.A. All shipments must comply with U.S.A export laws.

All shipments must comply with U.S.A export laws. No exceptions.

No exceptions.

“We Proudly Support Intrepid Fallen Heroes Fund that serves United States Military Personal experiencing the Invisible Wounds of War : Traumatic Brain Injury (TBI) and Post Traumatic Stress (PTS). Please visit website (www.fallenheroesfund.org) and help in their valiant effort”.

We hope that you will visit us again the next time you need industrial parts and make us your strategic purchasing partner.

Request for Quote